Greetings Again Dearest Reader,

In my last Epistle I wrote to you concerning the turntable at Durango. In this one posting I shall be discussing various aspects of Design Build (DB) versus Design Bid Build (DBB).

DB and DBB are relatively different construction methodologies that have pro's and con's to each. By having a company that can do the entire work in house from plans to project certain economies can be attained for both the builder and the client. By removing the bidding process a company can make more money with a flop that with a hit, wait wrong story. By removing the bidding process a company can make more money overall. It has a deeper level of involvement with the project and can ensure work for its employees for a longer period of time. The more entities that are involved in the project the less money that can be made by an individual player in general. By removing another player through DB, the chosen company can make more money.

DBB on the other hand allows smaller companies to have more opportunities for business. Due to the nature of DB, a company that wants to do this has to be relatively large to be able to handle all the necessary components. In DBB the companies involved can be more specialized and tailored to projects. This is not to say that all DB companies are large. DB companies can subcontract out most if not all the work if they so choose. This methodology would make it easier for smaller companies to get into DB.

Monday, February 27, 2017

Friday, February 24, 2017

A Sojourn to Durango

Good Mornings and Frosty Salutations to you all Readers,

Earlier this week I made the long drive down to Durango to go do some proper engineering staring at the Durango turntable. First I have to give a special thanks to everybody down at the Durango and Silverton, D&S. Everybody there was extremely pleasant and accommodating. In particular I'd like to thank Larry Beam and Randy Babcock for letting me come and look at the turntable.

Here is what the Durango turntable looks like. The picture is from the 60's as I neglected to get a good picture on Monday.

As you can see this was before an air motor was put on the turntable and it was still turned by hand. I do not envy turning a 37 on that. In addition to the air motor there are loops on the ring rail wheels for a tractor to pull the table if necessary, this will be an addition to the como turntable.

The purpose of my visit was primarily to determine how the turntable mounted on the center bearing and how the ring rail wheels were attached. Larry and Randy were incredibly helpful and their insight alone made the trip worth the drive. This table has been in service since 1920 when it replaced an earlier one. The table is from Alamosa and was cut down to fit in the Durango pit. The bridge itself was built in 1899 giving the bridge a current service life of 118 years and the table as it sits now 97 years. Considering the bridge is old enough to have been a doughboy in France it is doing remarkably well. However in talking with Larry and Randy they described the table as worn out. Many components are in need of significant repair or replacement and the table regularly requires significantly more maintenance and tweaking than they would prefer.

So getting to how the table mounts on the center bearing. The bearing sits on a cast pedistal about 20-24" off the concrete foundation block. About 3' off center either side are lateral plates held in with angle iron and rivets. Between the plates running longitudinally there are plate girders secured in place with rivets and angle iron. On the underside of these longitudinal plate girders is mounting bracket for the rocker plate. I managed to get some pictures however due to the poor lighting and crampt conditions they are not of the best quality for descriptive purposes.

This picture is in underneath the bridge looking towards the center.You can see the lateral plate girder previously described with the pedistal and rivet connections. Design of an equivalent set up for the como turntable is in process.

The ring rail wheels were my next biggest priority and much learning was had there. The current wheels we have are from a bridge crane, while nice they will require significant modification. The right rail wheels in Durango were very fat with no flange to accommodate the movement of the right rail over time. The como ring rail will be more secure than durango's however over the course of time with use and frost heaving it will move making the removal of the flange necessary at minimum. I am afraid I am going to have to curtail my blogging efforts here as blogspot does not take kindly to having pictures in the postings and the formatting is getting very difficult.

Above is the ring rail wheel assembly. You can see the hitch point in the side for a tractor if necessary. Larry told me of the trouble he's had with it and suggested I use a fat wheel with a beefy bronze bearing for como. Keep it simple and easy to maintain and adjust.

Thank you for visiting, come back soon!

Earlier this week I made the long drive down to Durango to go do some proper engineering staring at the Durango turntable. First I have to give a special thanks to everybody down at the Durango and Silverton, D&S. Everybody there was extremely pleasant and accommodating. In particular I'd like to thank Larry Beam and Randy Babcock for letting me come and look at the turntable.

Here is what the Durango turntable looks like. The picture is from the 60's as I neglected to get a good picture on Monday.

As you can see this was before an air motor was put on the turntable and it was still turned by hand. I do not envy turning a 37 on that. In addition to the air motor there are loops on the ring rail wheels for a tractor to pull the table if necessary, this will be an addition to the como turntable.

The purpose of my visit was primarily to determine how the turntable mounted on the center bearing and how the ring rail wheels were attached. Larry and Randy were incredibly helpful and their insight alone made the trip worth the drive. This table has been in service since 1920 when it replaced an earlier one. The table is from Alamosa and was cut down to fit in the Durango pit. The bridge itself was built in 1899 giving the bridge a current service life of 118 years and the table as it sits now 97 years. Considering the bridge is old enough to have been a doughboy in France it is doing remarkably well. However in talking with Larry and Randy they described the table as worn out. Many components are in need of significant repair or replacement and the table regularly requires significantly more maintenance and tweaking than they would prefer.

So getting to how the table mounts on the center bearing. The bearing sits on a cast pedistal about 20-24" off the concrete foundation block. About 3' off center either side are lateral plates held in with angle iron and rivets. Between the plates running longitudinally there are plate girders secured in place with rivets and angle iron. On the underside of these longitudinal plate girders is mounting bracket for the rocker plate. I managed to get some pictures however due to the poor lighting and crampt conditions they are not of the best quality for descriptive purposes.

This picture is in underneath the bridge looking towards the center.You can see the lateral plate girder previously described with the pedistal and rivet connections. Design of an equivalent set up for the como turntable is in process.

The ring rail wheels were my next biggest priority and much learning was had there. The current wheels we have are from a bridge crane, while nice they will require significant modification. The right rail wheels in Durango were very fat with no flange to accommodate the movement of the right rail over time. The como ring rail will be more secure than durango's however over the course of time with use and frost heaving it will move making the removal of the flange necessary at minimum. I am afraid I am going to have to curtail my blogging efforts here as blogspot does not take kindly to having pictures in the postings and the formatting is getting very difficult.

Above is the ring rail wheel assembly. You can see the hitch point in the side for a tractor if necessary. Larry told me of the trouble he's had with it and suggested I use a fat wheel with a beefy bronze bearing for como. Keep it simple and easy to maintain and adjust.

Thank you for visiting, come back soon!

Comments on the Design Bid Build activity

Greetings Once More Dearest Reader,

On Wednesday the 15th we did a Design-Bid-Build (DBB) activity concerning the building of a knex bridge. We were provided with the design and our job was to estimate the requisite materials and labor to produce a reasonable and profitable cost estimate.

Overall I thought the activity was pretty good. It was a good learning and team activity. For those unfamiliar with estimating I think it was a good exercise.

I would have appreciated being able to handle the materials during the estimating process. I grew up playing with knex but some of my team mates did not. So without a proper understanding of how they go together it's harder to make a proper estimate of time. I mean these are kids building toys not Faberge eggs.

I'm not an expert on bidding. The best I've done in that area is my work as a neighborhood handyman and doing budgets for History Colorado Grants. As well right now I'm in the process of rebuilding an historic railroad turntable which I am supposed to have a rough budget for in 3 weeks. I thought it was a valuable exercise, I was not familiar with the bond process but not surprised of its existence

Most teams appeared to be presaging their materials. In some cases it was done to an extent which would render them a potentially unfair advantage.However it was within the parameters of the project. Bending of the rules always happens but that's what lawyers are for.

I think it would be better to do the reading first then the activity. As well I would have appreciated more time in the beginning to get an understanding of the activity

On Wednesday the 15th we did a Design-Bid-Build (DBB) activity concerning the building of a knex bridge. We were provided with the design and our job was to estimate the requisite materials and labor to produce a reasonable and profitable cost estimate.

Overall I thought the activity was pretty good. It was a good learning and team activity. For those unfamiliar with estimating I think it was a good exercise.

I would have appreciated being able to handle the materials during the estimating process. I grew up playing with knex but some of my team mates did not. So without a proper understanding of how they go together it's harder to make a proper estimate of time. I mean these are kids building toys not Faberge eggs.

I'm not an expert on bidding. The best I've done in that area is my work as a neighborhood handyman and doing budgets for History Colorado Grants. As well right now I'm in the process of rebuilding an historic railroad turntable which I am supposed to have a rough budget for in 3 weeks. I thought it was a valuable exercise, I was not familiar with the bond process but not surprised of its existence

Most teams appeared to be presaging their materials. In some cases it was done to an extent which would render them a potentially unfair advantage.However it was within the parameters of the project. Bending of the rules always happens but that's what lawyers are for.

I think it would be better to do the reading first then the activity. As well I would have appreciated more time in the beginning to get an understanding of the activity

Wednesday, February 15, 2017

Modern Bridges and Medieval Castles

Dearest Reader,

Pardon my absence and relative tardiness, I have been exceedingly busy as of late.

So comparing the construction videos, here are the links to those who haven't watched them

Medieval Castle Construction

https://www.youtube.com/watch?v=CboJzrDhoSk&feature=youtu.be

New NY Bridge Construction

http://www.newnybridge.com/three-years-in-two-minutes-new-video-captures-construction-progress/

Both of these videos are astoundingly cool to say the lease and represent very different construction methodologies and practices. The castle is being hand built using historically accurate practices, from treadmill cranes to hand chiseling the pieces. The castle is being built by a few dozen people in their spare time. Comparing that to the bridge construction, modern equipment is being used by thousands of full time workers, contractors, and subcontractors to produce the end product. The comparison is fascinating. Between the two construction projects 800 years of advancement can be seen.

The skills required for each project are quite divergent and difficult to compare. In the castle you have stone masons doing work that is thousands of years old dating back to the beginning of civilization. Comparing that to the bridge with modern construction practices and equipment, as someone with a romantic love of history, there just seems to be more skill and art in the craft of the mason as employed in the castle. This is by no means a slight to the iron worker or crane operator, but the hands of nature of masonry, each stone being individually crafted by hand one hammer blow at a time, has such a romance and connection to it. As well the fact that they're doing work that has been done for millennia, that connection to the past to me is highly intriguing. Each cut stone or hewn timber has an intimacy with its craftsman. A human hand has handled and shaped each piece, leaving with it the signs of its maker that will last for many thousands of years. The bridge will last maybe a hundred years or more, the castle will easily last hundreds or thousands.

Pardon my absence and relative tardiness, I have been exceedingly busy as of late.

So comparing the construction videos, here are the links to those who haven't watched them

Medieval Castle Construction

https://www.youtube.com/watch?v=CboJzrDhoSk&feature=youtu.be

New NY Bridge Construction

http://www.newnybridge.com/three-years-in-two-minutes-new-video-captures-construction-progress/

Both of these videos are astoundingly cool to say the lease and represent very different construction methodologies and practices. The castle is being hand built using historically accurate practices, from treadmill cranes to hand chiseling the pieces. The castle is being built by a few dozen people in their spare time. Comparing that to the bridge construction, modern equipment is being used by thousands of full time workers, contractors, and subcontractors to produce the end product. The comparison is fascinating. Between the two construction projects 800 years of advancement can be seen.

The skills required for each project are quite divergent and difficult to compare. In the castle you have stone masons doing work that is thousands of years old dating back to the beginning of civilization. Comparing that to the bridge with modern construction practices and equipment, as someone with a romantic love of history, there just seems to be more skill and art in the craft of the mason as employed in the castle. This is by no means a slight to the iron worker or crane operator, but the hands of nature of masonry, each stone being individually crafted by hand one hammer blow at a time, has such a romance and connection to it. As well the fact that they're doing work that has been done for millennia, that connection to the past to me is highly intriguing. Each cut stone or hewn timber has an intimacy with its craftsman. A human hand has handled and shaped each piece, leaving with it the signs of its maker that will last for many thousands of years. The bridge will last maybe a hundred years or more, the castle will easily last hundreds or thousands.

Wednesday, February 8, 2017

It's hard to take measurements in Gloves

Greetings again Dearest Reader,

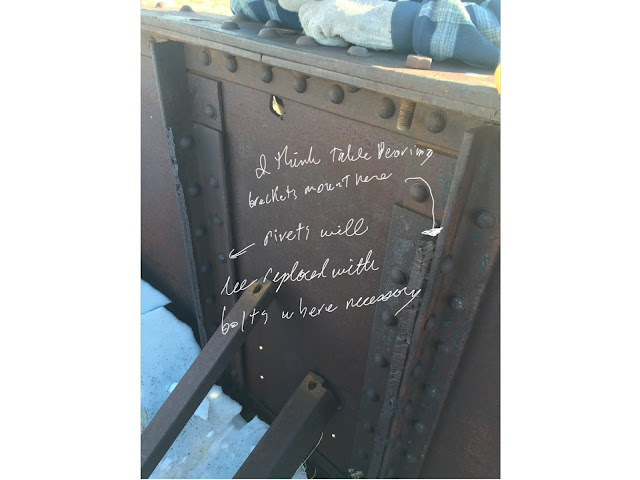

Now for a Como Update. Monday I made a trip down to South Park to take measurements and do some engineering staring. My measurement taking was good and my staring was revealing. As well the temperature was cold and windy as could be expected. After looking at the interior of the turntable side frames I could see where the pivot previously mounted and how we're going to mount the new pivot. Below are annotated pictures. I did a walk around of the table looking at the sheets of the table side frames. Despite their age, 130+ years, they are in remarkably good shape on the surface. Their appears to be no significant surface corrosion or pitting.

Inside the roundhouse I took measurements of the pivot and examined how the rocking plate and the bearing engage each other and how the bridge mounts to the rocking plate. Pictures will explain it better than I can. The top of the bearing has an arch which mates with a corresponding negative arch on the rocker plate. There is about 1.5 inch lip around the top of the rocker plate which I'm assuming is where the turntable mounts to it. I will be making a trip to Durango within the next month to see how their table is set up since this is a D&RGW turntable bearing and Durango has its original Grande turntable.

Here's the bridge itself.

Here's the pit and roundhouse

The bearing. I didn't get a good picture but in the top half of the bearing there is a hole that is threaded towards the bottom. I believe this is for a pin to keep the rocking plate from moving too much.

Here's the rocking plate, It is a solid casting so its rather heavy.

This is the interior side frame at the center of the table where it mounts to the bearing. You can see where the material was torched off. I believe that is where the mounting bracket attached to the side frame.

Here's the Depot, its adorable

Many thanks to Jeff Ramsey for helping me take measurements! That's all for now folks, stay tuned for more updates.

Leighton

Now for a Como Update. Monday I made a trip down to South Park to take measurements and do some engineering staring. My measurement taking was good and my staring was revealing. As well the temperature was cold and windy as could be expected. After looking at the interior of the turntable side frames I could see where the pivot previously mounted and how we're going to mount the new pivot. Below are annotated pictures. I did a walk around of the table looking at the sheets of the table side frames. Despite their age, 130+ years, they are in remarkably good shape on the surface. Their appears to be no significant surface corrosion or pitting.

Inside the roundhouse I took measurements of the pivot and examined how the rocking plate and the bearing engage each other and how the bridge mounts to the rocking plate. Pictures will explain it better than I can. The top of the bearing has an arch which mates with a corresponding negative arch on the rocker plate. There is about 1.5 inch lip around the top of the rocker plate which I'm assuming is where the turntable mounts to it. I will be making a trip to Durango within the next month to see how their table is set up since this is a D&RGW turntable bearing and Durango has its original Grande turntable.

Here's the bridge itself.

Here's the pit and roundhouse

The bearing. I didn't get a good picture but in the top half of the bearing there is a hole that is threaded towards the bottom. I believe this is for a pin to keep the rocking plate from moving too much.

Here's the rocking plate, It is a solid casting so its rather heavy.

This is the interior side frame at the center of the table where it mounts to the bearing. You can see where the material was torched off. I believe that is where the mounting bracket attached to the side frame.

Here's the Depot, its adorable

Many thanks to Jeff Ramsey for helping me take measurements! That's all for now folks, stay tuned for more updates.

Leighton

Construction Site Visit

Greetings again Dearest Reader,

Don't worry, there will be another Como update soon.

While sojourning to the Minneapolis for an ASCE conference me and various other people in this class made the rounds around downtown to observe the various construction sites in the area. The site we focused on was the reconstruction of a road from a more traditional road to an open mall, much like 16th St. Mall in Denver. The old road surface had been scraped off and the ground prepared for new concrete. The project was a good one to look at because over the course of several blocks you could see the development of the project. As you went down the street you could see the project in varying stages of progress going towards completion.

In terms of equipment there were various excavators and rollers on site. As well there was an office trailer.

It's interesting to see cities reinvesting in their downtown areas. For much of the post-war era the trend in community development has been to expand and focus the suburban areas. However in recent years the trend has been to refocus on urban city close areas. Downtown Minneapolis is a good example of this. Well I think that's enough about Minnesota so bye now!

Don't worry, there will be another Como update soon.

While sojourning to the Minneapolis for an ASCE conference me and various other people in this class made the rounds around downtown to observe the various construction sites in the area. The site we focused on was the reconstruction of a road from a more traditional road to an open mall, much like 16th St. Mall in Denver. The old road surface had been scraped off and the ground prepared for new concrete. The project was a good one to look at because over the course of several blocks you could see the development of the project. As you went down the street you could see the project in varying stages of progress going towards completion.

In terms of equipment there were various excavators and rollers on site. As well there was an office trailer.

It's interesting to see cities reinvesting in their downtown areas. For much of the post-war era the trend in community development has been to expand and focus the suburban areas. However in recent years the trend has been to refocus on urban city close areas. Downtown Minneapolis is a good example of this. Well I think that's enough about Minnesota so bye now!

Wednesday, February 1, 2017

thoughts on revit

Greetings Again Dearest Reader,

I come to you today in a state of sickness not health. Soon I shall be returning to my quarters for more dayquil and sleep to return by body to a state of good repair.

However before I can return to healing I must comment on my revit experiences, and if you may pardon the pun, I found it reviting. After a few hours of working in it it's starting to feel more intuitive. I can definitely see the value in this program and I expect to see it more in the future. I think being able to fully build the structure in the computer has immense value and that this program will only become more valuable. I wish that we had a class that was just learning how to use the major civil computer programs like revit and autocad.

I come to you today in a state of sickness not health. Soon I shall be returning to my quarters for more dayquil and sleep to return by body to a state of good repair.

However before I can return to healing I must comment on my revit experiences, and if you may pardon the pun, I found it reviting. After a few hours of working in it it's starting to feel more intuitive. I can definitely see the value in this program and I expect to see it more in the future. I think being able to fully build the structure in the computer has immense value and that this program will only become more valuable. I wish that we had a class that was just learning how to use the major civil computer programs like revit and autocad.

Subscribe to:

Posts (Atom)