Hello All,

Welcome to my final blog post. All future postings regarding the Como Turntable will be on the narrow gauge discussion forum. ngdiscussion.net

Food build is a conceptually good project however the work load was not equally shared between the design and construction teams. The design teams seemed to have a dramatically higher workload than the construction teams.

I learned a lot in this class however a lot of the stuff we learned won't really make sense until we try to apply it. Practical on the job training is more applicable in this context in my opinion. However with that in mind food build is a good way to apply these principles. If there could be a way to balance the workload that would be more appreciated.

From what I've learned from people older and wiser than me, unless you're locked in a room doing design work and sliding your drawings under the door you will need to be able to interact with people of various backgrounds and disciplines. I wish that the school offered more accounting, law, and non technical communications classes to enable us the students to speak more than engineer.

Signing off for the final time,

Leighton

Monday, May 8, 2017

Wednesday, April 26, 2017

Psyche I'm back!!

Greetings Again Reader,

Forgive my tardiness in my postings. Many late posts are in order and shall be done in due and expedient course.

Now to the matter of why I returned, the PENULTIMATE BLOG POST!!!! The last but one post. The almost but not really quite there post. Here it is

As to accidents on job sites the OSHA videos touched on most of what I had thought of. Poor safety use in equipment and being out of the line of sight of the operator are huge safety errors. As well it is very easy to get into trouble with ladders and high places, personally I had ladders. I had not considered trench based accidents in great detail.

In a construction or industrial context it is incredibly easy to get into trouble or danger. Being out of the line of sight for the operator is one that is particularly important to me. Inadequate fall protection is an easy way to die. From my own personal experience there have been a few times when I've almost fallen off of the top of a steam locomotive, an accident which would have either landed me in the hospital or the morgue. Many accidents occur due to people not being holistically aware of their situation. For example if they're moving a ladder are they thinking about what might be at the other end or just not letting the ladder fall over completely.

Going to the reading many of the same themes are seen again. Is everybody aware of what is going on at the job site? Was there a safety briefing? Are proper safety appliances being used? Is the equipment maintained? Is everything safe and suitable for service. Safety really isn't rocket science, its about taking things at a reasonable pace and making sure that all bases are covered and everybody knows what's going on and is acting with safety in mind,

RLM

Forgive my tardiness in my postings. Many late posts are in order and shall be done in due and expedient course.

Now to the matter of why I returned, the PENULTIMATE BLOG POST!!!! The last but one post. The almost but not really quite there post. Here it is

As to accidents on job sites the OSHA videos touched on most of what I had thought of. Poor safety use in equipment and being out of the line of sight of the operator are huge safety errors. As well it is very easy to get into trouble with ladders and high places, personally I had ladders. I had not considered trench based accidents in great detail.

In a construction or industrial context it is incredibly easy to get into trouble or danger. Being out of the line of sight for the operator is one that is particularly important to me. Inadequate fall protection is an easy way to die. From my own personal experience there have been a few times when I've almost fallen off of the top of a steam locomotive, an accident which would have either landed me in the hospital or the morgue. Many accidents occur due to people not being holistically aware of their situation. For example if they're moving a ladder are they thinking about what might be at the other end or just not letting the ladder fall over completely.

Going to the reading many of the same themes are seen again. Is everybody aware of what is going on at the job site? Was there a safety briefing? Are proper safety appliances being used? Is the equipment maintained? Is everything safe and suitable for service. Safety really isn't rocket science, its about taking things at a reasonable pace and making sure that all bases are covered and everybody knows what's going on and is acting with safety in mind,

RLM

Monday, April 3, 2017

return from the edge of the earth, thoughts on concrete and steel reading

Greetings Again Dearest Reader,

As is my occasional custom I have disappeared for some time, with ensuring tardiness towards other postings on this public-private forum. However much like a dirty penny or annoying relative I have made my not too much undesired return to entrance you with my attempts at wit and commentary on engineering practice.

Banter and prolixity aside let us get straight to the matter.

I quite enjoyed the CMU and steel readings. The steel was to a certain degree redundant however a nice cursory summation of much of what has been learned in other classes. The CMU reading I found highly interesting as I have yet to have the opportunity to study masonry design or practice in depth. I was not really aware of dry masonry construction before the reading. Looking back I've seen it in practice but I've never really put much thought into it myself. Personally I am most fond of wooden construction considering my predilections towards carpentry and joinery.

Cinder block construction is a highly common construction technique that has many benefits. Like all construction methods though, it requires significant skill and practice for an individual to achieve quality workmanship. Good brick laying requires consistency and attention to detail. Computers and machinery are frequently superior to man in those categories. This being the case, the job of a bricklayer is one that is highly susceptible to mechanization. Mechanization and automation is increasingly common in many areas of manufacturing and construction. With this in mind, one does have to wonder if this will a job that will exist and to what extent in the coming years. The work of a bricklayer may be like the movement of earth, once done by armies of hundreds by hand but now by a few in machines.

Your Resident Luddite,

RLM

As is my occasional custom I have disappeared for some time, with ensuring tardiness towards other postings on this public-private forum. However much like a dirty penny or annoying relative I have made my not too much undesired return to entrance you with my attempts at wit and commentary on engineering practice.

Banter and prolixity aside let us get straight to the matter.

I quite enjoyed the CMU and steel readings. The steel was to a certain degree redundant however a nice cursory summation of much of what has been learned in other classes. The CMU reading I found highly interesting as I have yet to have the opportunity to study masonry design or practice in depth. I was not really aware of dry masonry construction before the reading. Looking back I've seen it in practice but I've never really put much thought into it myself. Personally I am most fond of wooden construction considering my predilections towards carpentry and joinery.

Cinder block construction is a highly common construction technique that has many benefits. Like all construction methods though, it requires significant skill and practice for an individual to achieve quality workmanship. Good brick laying requires consistency and attention to detail. Computers and machinery are frequently superior to man in those categories. This being the case, the job of a bricklayer is one that is highly susceptible to mechanization. Mechanization and automation is increasingly common in many areas of manufacturing and construction. With this in mind, one does have to wonder if this will a job that will exist and to what extent in the coming years. The work of a bricklayer may be like the movement of earth, once done by armies of hundreds by hand but now by a few in machines.

Your Resident Luddite,

RLM

Wednesday, March 8, 2017

Greetings Again Dearest Reader,

I found the spec writing project very interesting and pleasantly absurd. I found it funny to write out in formal language the specs for scrambled eggs. It's a very valuable exercise. We learn a lot about technical writing but we don't often transition over to legal writing, which while similar has some differences in tone, format, and formality. I had a layman's law class in high school where I got to read a lot of legal documents and court briefs. I have some knowledge of that style of writing but not enough to suit my tastes.

As engineers, as I understand it, don't actually spend as much time as one would think actually doing engineering. The legal and financial aspects of a project are often highly time consuming and take precedence over much actual engineering work. This underlies the necessity for development of interpersonal skills not only with other persons of an engineering persuasion but people from financial and legal disciplines. The engineering side of a project is typically more simple and straightforward than the legal or financial side or the interpersonal dealings involved there in.

I found the spec writing project very interesting and pleasantly absurd. I found it funny to write out in formal language the specs for scrambled eggs. It's a very valuable exercise. We learn a lot about technical writing but we don't often transition over to legal writing, which while similar has some differences in tone, format, and formality. I had a layman's law class in high school where I got to read a lot of legal documents and court briefs. I have some knowledge of that style of writing but not enough to suit my tastes.

As engineers, as I understand it, don't actually spend as much time as one would think actually doing engineering. The legal and financial aspects of a project are often highly time consuming and take precedence over much actual engineering work. This underlies the necessity for development of interpersonal skills not only with other persons of an engineering persuasion but people from financial and legal disciplines. The engineering side of a project is typically more simple and straightforward than the legal or financial side or the interpersonal dealings involved there in.

Monday, February 27, 2017

thoughts on Design Build v Design Bid Build

Greetings Again Dearest Reader,

In my last Epistle I wrote to you concerning the turntable at Durango. In this one posting I shall be discussing various aspects of Design Build (DB) versus Design Bid Build (DBB).

DB and DBB are relatively different construction methodologies that have pro's and con's to each. By having a company that can do the entire work in house from plans to project certain economies can be attained for both the builder and the client. By removing the bidding process a company can make more money with a flop that with a hit, wait wrong story. By removing the bidding process a company can make more money overall. It has a deeper level of involvement with the project and can ensure work for its employees for a longer period of time. The more entities that are involved in the project the less money that can be made by an individual player in general. By removing another player through DB, the chosen company can make more money.

DBB on the other hand allows smaller companies to have more opportunities for business. Due to the nature of DB, a company that wants to do this has to be relatively large to be able to handle all the necessary components. In DBB the companies involved can be more specialized and tailored to projects. This is not to say that all DB companies are large. DB companies can subcontract out most if not all the work if they so choose. This methodology would make it easier for smaller companies to get into DB.

In my last Epistle I wrote to you concerning the turntable at Durango. In this one posting I shall be discussing various aspects of Design Build (DB) versus Design Bid Build (DBB).

DB and DBB are relatively different construction methodologies that have pro's and con's to each. By having a company that can do the entire work in house from plans to project certain economies can be attained for both the builder and the client. By removing the bidding process a company can make more money with a flop that with a hit, wait wrong story. By removing the bidding process a company can make more money overall. It has a deeper level of involvement with the project and can ensure work for its employees for a longer period of time. The more entities that are involved in the project the less money that can be made by an individual player in general. By removing another player through DB, the chosen company can make more money.

DBB on the other hand allows smaller companies to have more opportunities for business. Due to the nature of DB, a company that wants to do this has to be relatively large to be able to handle all the necessary components. In DBB the companies involved can be more specialized and tailored to projects. This is not to say that all DB companies are large. DB companies can subcontract out most if not all the work if they so choose. This methodology would make it easier for smaller companies to get into DB.

Friday, February 24, 2017

A Sojourn to Durango

Good Mornings and Frosty Salutations to you all Readers,

Earlier this week I made the long drive down to Durango to go do some proper engineering staring at the Durango turntable. First I have to give a special thanks to everybody down at the Durango and Silverton, D&S. Everybody there was extremely pleasant and accommodating. In particular I'd like to thank Larry Beam and Randy Babcock for letting me come and look at the turntable.

Here is what the Durango turntable looks like. The picture is from the 60's as I neglected to get a good picture on Monday.

As you can see this was before an air motor was put on the turntable and it was still turned by hand. I do not envy turning a 37 on that. In addition to the air motor there are loops on the ring rail wheels for a tractor to pull the table if necessary, this will be an addition to the como turntable.

The purpose of my visit was primarily to determine how the turntable mounted on the center bearing and how the ring rail wheels were attached. Larry and Randy were incredibly helpful and their insight alone made the trip worth the drive. This table has been in service since 1920 when it replaced an earlier one. The table is from Alamosa and was cut down to fit in the Durango pit. The bridge itself was built in 1899 giving the bridge a current service life of 118 years and the table as it sits now 97 years. Considering the bridge is old enough to have been a doughboy in France it is doing remarkably well. However in talking with Larry and Randy they described the table as worn out. Many components are in need of significant repair or replacement and the table regularly requires significantly more maintenance and tweaking than they would prefer.

So getting to how the table mounts on the center bearing. The bearing sits on a cast pedistal about 20-24" off the concrete foundation block. About 3' off center either side are lateral plates held in with angle iron and rivets. Between the plates running longitudinally there are plate girders secured in place with rivets and angle iron. On the underside of these longitudinal plate girders is mounting bracket for the rocker plate. I managed to get some pictures however due to the poor lighting and crampt conditions they are not of the best quality for descriptive purposes.

This picture is in underneath the bridge looking towards the center.You can see the lateral plate girder previously described with the pedistal and rivet connections. Design of an equivalent set up for the como turntable is in process.

The ring rail wheels were my next biggest priority and much learning was had there. The current wheels we have are from a bridge crane, while nice they will require significant modification. The right rail wheels in Durango were very fat with no flange to accommodate the movement of the right rail over time. The como ring rail will be more secure than durango's however over the course of time with use and frost heaving it will move making the removal of the flange necessary at minimum. I am afraid I am going to have to curtail my blogging efforts here as blogspot does not take kindly to having pictures in the postings and the formatting is getting very difficult.

Above is the ring rail wheel assembly. You can see the hitch point in the side for a tractor if necessary. Larry told me of the trouble he's had with it and suggested I use a fat wheel with a beefy bronze bearing for como. Keep it simple and easy to maintain and adjust.

Thank you for visiting, come back soon!

Earlier this week I made the long drive down to Durango to go do some proper engineering staring at the Durango turntable. First I have to give a special thanks to everybody down at the Durango and Silverton, D&S. Everybody there was extremely pleasant and accommodating. In particular I'd like to thank Larry Beam and Randy Babcock for letting me come and look at the turntable.

Here is what the Durango turntable looks like. The picture is from the 60's as I neglected to get a good picture on Monday.

As you can see this was before an air motor was put on the turntable and it was still turned by hand. I do not envy turning a 37 on that. In addition to the air motor there are loops on the ring rail wheels for a tractor to pull the table if necessary, this will be an addition to the como turntable.

The purpose of my visit was primarily to determine how the turntable mounted on the center bearing and how the ring rail wheels were attached. Larry and Randy were incredibly helpful and their insight alone made the trip worth the drive. This table has been in service since 1920 when it replaced an earlier one. The table is from Alamosa and was cut down to fit in the Durango pit. The bridge itself was built in 1899 giving the bridge a current service life of 118 years and the table as it sits now 97 years. Considering the bridge is old enough to have been a doughboy in France it is doing remarkably well. However in talking with Larry and Randy they described the table as worn out. Many components are in need of significant repair or replacement and the table regularly requires significantly more maintenance and tweaking than they would prefer.

So getting to how the table mounts on the center bearing. The bearing sits on a cast pedistal about 20-24" off the concrete foundation block. About 3' off center either side are lateral plates held in with angle iron and rivets. Between the plates running longitudinally there are plate girders secured in place with rivets and angle iron. On the underside of these longitudinal plate girders is mounting bracket for the rocker plate. I managed to get some pictures however due to the poor lighting and crampt conditions they are not of the best quality for descriptive purposes.

This picture is in underneath the bridge looking towards the center.You can see the lateral plate girder previously described with the pedistal and rivet connections. Design of an equivalent set up for the como turntable is in process.

The ring rail wheels were my next biggest priority and much learning was had there. The current wheels we have are from a bridge crane, while nice they will require significant modification. The right rail wheels in Durango were very fat with no flange to accommodate the movement of the right rail over time. The como ring rail will be more secure than durango's however over the course of time with use and frost heaving it will move making the removal of the flange necessary at minimum. I am afraid I am going to have to curtail my blogging efforts here as blogspot does not take kindly to having pictures in the postings and the formatting is getting very difficult.

Above is the ring rail wheel assembly. You can see the hitch point in the side for a tractor if necessary. Larry told me of the trouble he's had with it and suggested I use a fat wheel with a beefy bronze bearing for como. Keep it simple and easy to maintain and adjust.

Thank you for visiting, come back soon!

Comments on the Design Bid Build activity

Greetings Once More Dearest Reader,

On Wednesday the 15th we did a Design-Bid-Build (DBB) activity concerning the building of a knex bridge. We were provided with the design and our job was to estimate the requisite materials and labor to produce a reasonable and profitable cost estimate.

Overall I thought the activity was pretty good. It was a good learning and team activity. For those unfamiliar with estimating I think it was a good exercise.

I would have appreciated being able to handle the materials during the estimating process. I grew up playing with knex but some of my team mates did not. So without a proper understanding of how they go together it's harder to make a proper estimate of time. I mean these are kids building toys not Faberge eggs.

I'm not an expert on bidding. The best I've done in that area is my work as a neighborhood handyman and doing budgets for History Colorado Grants. As well right now I'm in the process of rebuilding an historic railroad turntable which I am supposed to have a rough budget for in 3 weeks. I thought it was a valuable exercise, I was not familiar with the bond process but not surprised of its existence

Most teams appeared to be presaging their materials. In some cases it was done to an extent which would render them a potentially unfair advantage.However it was within the parameters of the project. Bending of the rules always happens but that's what lawyers are for.

I think it would be better to do the reading first then the activity. As well I would have appreciated more time in the beginning to get an understanding of the activity

On Wednesday the 15th we did a Design-Bid-Build (DBB) activity concerning the building of a knex bridge. We were provided with the design and our job was to estimate the requisite materials and labor to produce a reasonable and profitable cost estimate.

Overall I thought the activity was pretty good. It was a good learning and team activity. For those unfamiliar with estimating I think it was a good exercise.

I would have appreciated being able to handle the materials during the estimating process. I grew up playing with knex but some of my team mates did not. So without a proper understanding of how they go together it's harder to make a proper estimate of time. I mean these are kids building toys not Faberge eggs.

I'm not an expert on bidding. The best I've done in that area is my work as a neighborhood handyman and doing budgets for History Colorado Grants. As well right now I'm in the process of rebuilding an historic railroad turntable which I am supposed to have a rough budget for in 3 weeks. I thought it was a valuable exercise, I was not familiar with the bond process but not surprised of its existence

Most teams appeared to be presaging their materials. In some cases it was done to an extent which would render them a potentially unfair advantage.However it was within the parameters of the project. Bending of the rules always happens but that's what lawyers are for.

I think it would be better to do the reading first then the activity. As well I would have appreciated more time in the beginning to get an understanding of the activity

Wednesday, February 15, 2017

Modern Bridges and Medieval Castles

Dearest Reader,

Pardon my absence and relative tardiness, I have been exceedingly busy as of late.

So comparing the construction videos, here are the links to those who haven't watched them

Medieval Castle Construction

https://www.youtube.com/watch?v=CboJzrDhoSk&feature=youtu.be

New NY Bridge Construction

http://www.newnybridge.com/three-years-in-two-minutes-new-video-captures-construction-progress/

Both of these videos are astoundingly cool to say the lease and represent very different construction methodologies and practices. The castle is being hand built using historically accurate practices, from treadmill cranes to hand chiseling the pieces. The castle is being built by a few dozen people in their spare time. Comparing that to the bridge construction, modern equipment is being used by thousands of full time workers, contractors, and subcontractors to produce the end product. The comparison is fascinating. Between the two construction projects 800 years of advancement can be seen.

The skills required for each project are quite divergent and difficult to compare. In the castle you have stone masons doing work that is thousands of years old dating back to the beginning of civilization. Comparing that to the bridge with modern construction practices and equipment, as someone with a romantic love of history, there just seems to be more skill and art in the craft of the mason as employed in the castle. This is by no means a slight to the iron worker or crane operator, but the hands of nature of masonry, each stone being individually crafted by hand one hammer blow at a time, has such a romance and connection to it. As well the fact that they're doing work that has been done for millennia, that connection to the past to me is highly intriguing. Each cut stone or hewn timber has an intimacy with its craftsman. A human hand has handled and shaped each piece, leaving with it the signs of its maker that will last for many thousands of years. The bridge will last maybe a hundred years or more, the castle will easily last hundreds or thousands.

Pardon my absence and relative tardiness, I have been exceedingly busy as of late.

So comparing the construction videos, here are the links to those who haven't watched them

Medieval Castle Construction

https://www.youtube.com/watch?v=CboJzrDhoSk&feature=youtu.be

New NY Bridge Construction

http://www.newnybridge.com/three-years-in-two-minutes-new-video-captures-construction-progress/

Both of these videos are astoundingly cool to say the lease and represent very different construction methodologies and practices. The castle is being hand built using historically accurate practices, from treadmill cranes to hand chiseling the pieces. The castle is being built by a few dozen people in their spare time. Comparing that to the bridge construction, modern equipment is being used by thousands of full time workers, contractors, and subcontractors to produce the end product. The comparison is fascinating. Between the two construction projects 800 years of advancement can be seen.

The skills required for each project are quite divergent and difficult to compare. In the castle you have stone masons doing work that is thousands of years old dating back to the beginning of civilization. Comparing that to the bridge with modern construction practices and equipment, as someone with a romantic love of history, there just seems to be more skill and art in the craft of the mason as employed in the castle. This is by no means a slight to the iron worker or crane operator, but the hands of nature of masonry, each stone being individually crafted by hand one hammer blow at a time, has such a romance and connection to it. As well the fact that they're doing work that has been done for millennia, that connection to the past to me is highly intriguing. Each cut stone or hewn timber has an intimacy with its craftsman. A human hand has handled and shaped each piece, leaving with it the signs of its maker that will last for many thousands of years. The bridge will last maybe a hundred years or more, the castle will easily last hundreds or thousands.

Wednesday, February 8, 2017

It's hard to take measurements in Gloves

Greetings again Dearest Reader,

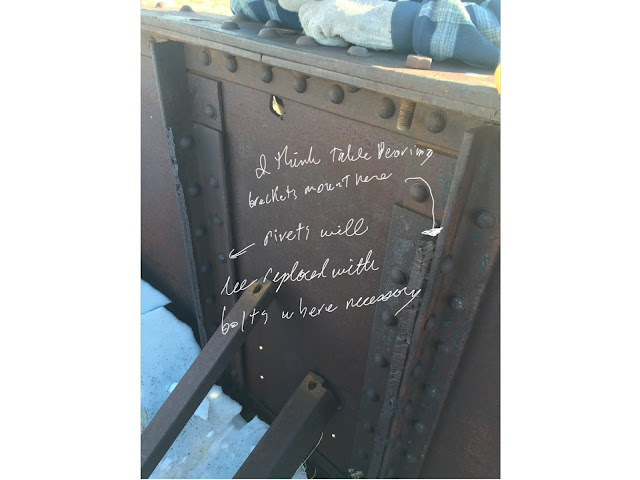

Now for a Como Update. Monday I made a trip down to South Park to take measurements and do some engineering staring. My measurement taking was good and my staring was revealing. As well the temperature was cold and windy as could be expected. After looking at the interior of the turntable side frames I could see where the pivot previously mounted and how we're going to mount the new pivot. Below are annotated pictures. I did a walk around of the table looking at the sheets of the table side frames. Despite their age, 130+ years, they are in remarkably good shape on the surface. Their appears to be no significant surface corrosion or pitting.

Inside the roundhouse I took measurements of the pivot and examined how the rocking plate and the bearing engage each other and how the bridge mounts to the rocking plate. Pictures will explain it better than I can. The top of the bearing has an arch which mates with a corresponding negative arch on the rocker plate. There is about 1.5 inch lip around the top of the rocker plate which I'm assuming is where the turntable mounts to it. I will be making a trip to Durango within the next month to see how their table is set up since this is a D&RGW turntable bearing and Durango has its original Grande turntable.

Here's the bridge itself.

Here's the pit and roundhouse

The bearing. I didn't get a good picture but in the top half of the bearing there is a hole that is threaded towards the bottom. I believe this is for a pin to keep the rocking plate from moving too much.

Here's the rocking plate, It is a solid casting so its rather heavy.

This is the interior side frame at the center of the table where it mounts to the bearing. You can see where the material was torched off. I believe that is where the mounting bracket attached to the side frame.

Here's the Depot, its adorable

Many thanks to Jeff Ramsey for helping me take measurements! That's all for now folks, stay tuned for more updates.

Leighton

Now for a Como Update. Monday I made a trip down to South Park to take measurements and do some engineering staring. My measurement taking was good and my staring was revealing. As well the temperature was cold and windy as could be expected. After looking at the interior of the turntable side frames I could see where the pivot previously mounted and how we're going to mount the new pivot. Below are annotated pictures. I did a walk around of the table looking at the sheets of the table side frames. Despite their age, 130+ years, they are in remarkably good shape on the surface. Their appears to be no significant surface corrosion or pitting.

Inside the roundhouse I took measurements of the pivot and examined how the rocking plate and the bearing engage each other and how the bridge mounts to the rocking plate. Pictures will explain it better than I can. The top of the bearing has an arch which mates with a corresponding negative arch on the rocker plate. There is about 1.5 inch lip around the top of the rocker plate which I'm assuming is where the turntable mounts to it. I will be making a trip to Durango within the next month to see how their table is set up since this is a D&RGW turntable bearing and Durango has its original Grande turntable.

Here's the bridge itself.

Here's the pit and roundhouse

The bearing. I didn't get a good picture but in the top half of the bearing there is a hole that is threaded towards the bottom. I believe this is for a pin to keep the rocking plate from moving too much.

Here's the rocking plate, It is a solid casting so its rather heavy.

This is the interior side frame at the center of the table where it mounts to the bearing. You can see where the material was torched off. I believe that is where the mounting bracket attached to the side frame.

Here's the Depot, its adorable

Many thanks to Jeff Ramsey for helping me take measurements! That's all for now folks, stay tuned for more updates.

Leighton

Construction Site Visit

Greetings again Dearest Reader,

Don't worry, there will be another Como update soon.

While sojourning to the Minneapolis for an ASCE conference me and various other people in this class made the rounds around downtown to observe the various construction sites in the area. The site we focused on was the reconstruction of a road from a more traditional road to an open mall, much like 16th St. Mall in Denver. The old road surface had been scraped off and the ground prepared for new concrete. The project was a good one to look at because over the course of several blocks you could see the development of the project. As you went down the street you could see the project in varying stages of progress going towards completion.

In terms of equipment there were various excavators and rollers on site. As well there was an office trailer.

It's interesting to see cities reinvesting in their downtown areas. For much of the post-war era the trend in community development has been to expand and focus the suburban areas. However in recent years the trend has been to refocus on urban city close areas. Downtown Minneapolis is a good example of this. Well I think that's enough about Minnesota so bye now!

Don't worry, there will be another Como update soon.

While sojourning to the Minneapolis for an ASCE conference me and various other people in this class made the rounds around downtown to observe the various construction sites in the area. The site we focused on was the reconstruction of a road from a more traditional road to an open mall, much like 16th St. Mall in Denver. The old road surface had been scraped off and the ground prepared for new concrete. The project was a good one to look at because over the course of several blocks you could see the development of the project. As you went down the street you could see the project in varying stages of progress going towards completion.

In terms of equipment there were various excavators and rollers on site. As well there was an office trailer.

It's interesting to see cities reinvesting in their downtown areas. For much of the post-war era the trend in community development has been to expand and focus the suburban areas. However in recent years the trend has been to refocus on urban city close areas. Downtown Minneapolis is a good example of this. Well I think that's enough about Minnesota so bye now!

Wednesday, February 1, 2017

thoughts on revit

Greetings Again Dearest Reader,

I come to you today in a state of sickness not health. Soon I shall be returning to my quarters for more dayquil and sleep to return by body to a state of good repair.

However before I can return to healing I must comment on my revit experiences, and if you may pardon the pun, I found it reviting. After a few hours of working in it it's starting to feel more intuitive. I can definitely see the value in this program and I expect to see it more in the future. I think being able to fully build the structure in the computer has immense value and that this program will only become more valuable. I wish that we had a class that was just learning how to use the major civil computer programs like revit and autocad.

I come to you today in a state of sickness not health. Soon I shall be returning to my quarters for more dayquil and sleep to return by body to a state of good repair.

However before I can return to healing I must comment on my revit experiences, and if you may pardon the pun, I found it reviting. After a few hours of working in it it's starting to feel more intuitive. I can definitely see the value in this program and I expect to see it more in the future. I think being able to fully build the structure in the computer has immense value and that this program will only become more valuable. I wish that we had a class that was just learning how to use the major civil computer programs like revit and autocad.

Friday, January 27, 2017

Live Blogging Continued

Hello Again Dearest Reader,

I'm having to switch to a new post because the old one had gotten too long for the program to be happy.

CDOT speaker continued

I70 expansion,

Construction begins early 2018 for the i25 to chambers trenching

Westbound express lane in the mountains begins soon

Eventually express lanes between FoCo and Denver, starting at each end and working towards the middle

He wants to expand the highways as needed and if the state and the taxpayers pony's up the cash then he'll build as much as he can

It's our responsibility to turn over a system to our kids that's better than we found it

1:20

James Ecklund

Colorado Water and why you should care

Water is light years ahead and behind of transportation

How we're ahead

- Headwaters state

- regional round tables put together basic implementation plans

I'm having to switch to a new post because the old one had gotten too long for the program to be happy.

CDOT speaker continued

I70 expansion,

Construction begins early 2018 for the i25 to chambers trenching

Westbound express lane in the mountains begins soon

Eventually express lanes between FoCo and Denver, starting at each end and working towards the middle

He wants to expand the highways as needed and if the state and the taxpayers pony's up the cash then he'll build as much as he can

It's our responsibility to turn over a system to our kids that's better than we found it

1:20

James Ecklund

Colorado Water and why you should care

Water is light years ahead and behind of transportation

How we're ahead

- Headwaters state

- regional round tables put together basic implementation plans

Live blogging annual CCA Conference

Good Morning Dearest Reader,

Welcome to my live blogging of the 84th Annual CCA Conference in Westminster

Key note speaker

8:35

Changing trends in OSHA. OSHA has been transitioning from action specific to programmatic regulation. Their goal is to interpret the code to get your money. The official company program has to be safety oriented, there need to be official fully documented company trainings with all the bases covered. All your training needs to be fully recorded, stuck to a fixed schedule, sign in sheets, and no ambiguity. Safety is about overall company policy.

Run from all liability

8:50

Republican presidents when they come into office they reduce funding for OSHA without shrinking the department. As a result citations increase to feed the machine and offset lost revenue.

Your safety committees need to actually work. Treat your people good and they'll comply with safety rules. Buy your workers pizza, let them know they're appreciated. Care about your workers and they'll do what you want. Involve everyone and keep everyone engaged and active. If everybody is enfranchised and actively care about what they do, safety will follow

9:15

PDAC

Plan

Decide

Act

Check

In all you do, do these things. Listen, Learn, and Lead. Convince your workers that you actually do care about them.

Effectively, in my own words, read a Dale Carnegie book

12:30

Speaker of the Colorado House. The population is growing and the state transportation infrastructure needs to grow to catch up. Gas taxes have not been updated since 1991 and as such funding has fallen and the infrastructure has suffered. I can't see her hands, not the best body language. Comprehensive plan needs to be developed to address colorado's transportation needs.

12:45

President of the Colorado Senate. The CCA is an important infrastructure advocacy group in the state.

How do we show good faith towards the taxpayer? How can we best prioritize funds for projects and programs to suit the needs of Colorado? We want to change housing and construction statutes so that more condos and multi-family dwellings can be built. This would allow for entry level housing to be built in the metro area to ease burdens on the rental market.

12:55

The Senate President was very short (Verbally not Physically). The Director of CDOT. The purpose of CDOT, to save lives and make lives better by proving freedom, connection, and experience through travel.

A 10% decrease in traffic congestion results in a 1% increase in economic productivity.

Almost 9 Billion dollars in unfunded highway projects.

2.5 billion in high priority projects

SB 228, senate bill allocating funds, less than 200 million allocated

72% of funding for transportation comes from federal government

Per capita transportation expenditures have decreased by half since 1991.

8i7

Welcome to my live blogging of the 84th Annual CCA Conference in Westminster

Key note speaker

8:35

Changing trends in OSHA. OSHA has been transitioning from action specific to programmatic regulation. Their goal is to interpret the code to get your money. The official company program has to be safety oriented, there need to be official fully documented company trainings with all the bases covered. All your training needs to be fully recorded, stuck to a fixed schedule, sign in sheets, and no ambiguity. Safety is about overall company policy.

Run from all liability

8:50

Republican presidents when they come into office they reduce funding for OSHA without shrinking the department. As a result citations increase to feed the machine and offset lost revenue.

Your safety committees need to actually work. Treat your people good and they'll comply with safety rules. Buy your workers pizza, let them know they're appreciated. Care about your workers and they'll do what you want. Involve everyone and keep everyone engaged and active. If everybody is enfranchised and actively care about what they do, safety will follow

9:15

PDAC

Plan

Decide

Act

Check

In all you do, do these things. Listen, Learn, and Lead. Convince your workers that you actually do care about them.

Effectively, in my own words, read a Dale Carnegie book

12:30

Speaker of the Colorado House. The population is growing and the state transportation infrastructure needs to grow to catch up. Gas taxes have not been updated since 1991 and as such funding has fallen and the infrastructure has suffered. I can't see her hands, not the best body language. Comprehensive plan needs to be developed to address colorado's transportation needs.

12:45

President of the Colorado Senate. The CCA is an important infrastructure advocacy group in the state.

How do we show good faith towards the taxpayer? How can we best prioritize funds for projects and programs to suit the needs of Colorado? We want to change housing and construction statutes so that more condos and multi-family dwellings can be built. This would allow for entry level housing to be built in the metro area to ease burdens on the rental market.

12:55

The Senate President was very short (Verbally not Physically). The Director of CDOT. The purpose of CDOT, to save lives and make lives better by proving freedom, connection, and experience through travel.

A 10% decrease in traffic congestion results in a 1% increase in economic productivity.

Almost 9 Billion dollars in unfunded highway projects.

2.5 billion in high priority projects

SB 228, senate bill allocating funds, less than 200 million allocated

72% of funding for transportation comes from federal government

Per capita transportation expenditures have decreased by half since 1991.

8i7

Monday, January 23, 2017

3-900 compulsory blog post

Hello Again Dearest Reader,

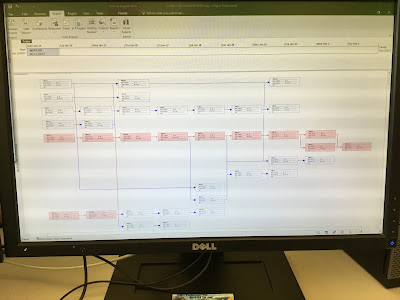

Due to unfortunate illness I was unable to be in class last Wednesday so I have yet to do the network by hand however here is my poor attempt at doing on in project

I am by no means proficient in Microsoft Project at this time however I hope this improves. I would say this network is reasonably sensitive. There's more than one prescribed course path to get a degree but its still pretty restricted.

As to the addition of corequisites, I would say that I would first try to become more proficient in project so I can utilize the tools available to me.

Hand made v. Computer Generated Schedule, I prefer hand made at this point. I'm not familiar enough to be comfortable using scheduling programs yet. My preferred technique for project scheduling is getting the relevant people around a table and using a white board to get everybody on the same page and figure out when stuff needs to be done.

My biggest takeaways from today's readings really were understanding prerequisites in scheduling. Construction management honestly seems like glorified cat herding with various disparate contractors and subcontractors making sure that at no time the cart is put before the horse.

I think the litigious nature of construction is somewhat of an annoyance that will continue into the future. As costs, particularly labor and insurance, continue to rise delays will become costlier and as such people will have even more impetus for pursuing compensation through legal action

Due to unfortunate illness I was unable to be in class last Wednesday so I have yet to do the network by hand however here is my poor attempt at doing on in project

I am by no means proficient in Microsoft Project at this time however I hope this improves. I would say this network is reasonably sensitive. There's more than one prescribed course path to get a degree but its still pretty restricted.

As to the addition of corequisites, I would say that I would first try to become more proficient in project so I can utilize the tools available to me.

Hand made v. Computer Generated Schedule, I prefer hand made at this point. I'm not familiar enough to be comfortable using scheduling programs yet. My preferred technique for project scheduling is getting the relevant people around a table and using a white board to get everybody on the same page and figure out when stuff needs to be done.

My biggest takeaways from today's readings really were understanding prerequisites in scheduling. Construction management honestly seems like glorified cat herding with various disparate contractors and subcontractors making sure that at no time the cart is put before the horse.

I think the litigious nature of construction is somewhat of an annoyance that will continue into the future. As costs, particularly labor and insurance, continue to rise delays will become costlier and as such people will have even more impetus for pursuing compensation through legal action

Como Turntable Progress

Dearest Reader,

Last week I met with the former owner of the Como Roundhouse, Mr. Bill Kazel, and we discussed the reconstruction of the turntable. While he has sold the roundhouse and adjoining property to its current owner he is still heavily involved with the restoration. He gave me a number of wonderful drawings that he and a few others had done over the years.

The turntable presents many interesting challenges considering it is probably from the 1880's. The table that is currently there is believed to be the table that was removed in 1910 when the pit was lined with concrete. The sides of the turntable bridge were separated at some point and the bridge side frames were used as a structural component in a building in downtown Denver for some time. During the reconstruction of the Georgetown Loop RR the building was torn down and somebody recognized it as a turntable. Initially it was thought to be the Georgetown turntable. However upon further investigation it was discovered to be the Como Turntable, being of a different style than the Georgetown one. In the middle of that the turntable side frames were rejoined by the Sea Bee's rebuilding the railroad. However when they did that they made it about a foot wider than it had originally been, luckily it will still fit in the pit comfortably.

The biggest challenge in the reconstruction of the turntable is the mounting of the bridge to the pivot. The pivot that is being used is of a different style than used originally and there are few signs of how the pivot mounted in the table are left in the bridge. So a new design will need to be made. Also to be considered is the material and construction of the bridge. The bridge is most likely iron or very poor grade steel. Being constructed in the late 19th century in the West it is very likely that it is iron, and therefore cannot be reliably welded. The original side frames are riveted together with the cross members from the 1970's reassembly bolted in place. In thinking about this the mounting plate connection for the pivot will be bolted in place. It would appear to the that the original mounting bracket was riveted into the side frame at a joint judging by the existing torched material. At this time we will probably torch out some of the rivets at the connection point then bolt the pivot mounting bracket in there. If necessary for historical accuracy the exposed heads of the bolts may be riveted over

As well Bill and I discussed some of the parameters for turntable construction and improvements. To keep with the historic nature of the site and keep modern safety considerations in mind, reconstruciton is done to an aesthetically pleasing but functionally safe standard. For example the new locking mechanism to lock the turntable to the tracks will be moved outside the rails to eliminate the need for someone to be in the gauge to lock the turntable. As well the new turntable arms will be made of steel and made to look like wood in all likelihood. Wooden arms are nice but they can break and require more maintenance.

Last week I met with the former owner of the Como Roundhouse, Mr. Bill Kazel, and we discussed the reconstruction of the turntable. While he has sold the roundhouse and adjoining property to its current owner he is still heavily involved with the restoration. He gave me a number of wonderful drawings that he and a few others had done over the years.

The turntable presents many interesting challenges considering it is probably from the 1880's. The table that is currently there is believed to be the table that was removed in 1910 when the pit was lined with concrete. The sides of the turntable bridge were separated at some point and the bridge side frames were used as a structural component in a building in downtown Denver for some time. During the reconstruction of the Georgetown Loop RR the building was torn down and somebody recognized it as a turntable. Initially it was thought to be the Georgetown turntable. However upon further investigation it was discovered to be the Como Turntable, being of a different style than the Georgetown one. In the middle of that the turntable side frames were rejoined by the Sea Bee's rebuilding the railroad. However when they did that they made it about a foot wider than it had originally been, luckily it will still fit in the pit comfortably.

The biggest challenge in the reconstruction of the turntable is the mounting of the bridge to the pivot. The pivot that is being used is of a different style than used originally and there are few signs of how the pivot mounted in the table are left in the bridge. So a new design will need to be made. Also to be considered is the material and construction of the bridge. The bridge is most likely iron or very poor grade steel. Being constructed in the late 19th century in the West it is very likely that it is iron, and therefore cannot be reliably welded. The original side frames are riveted together with the cross members from the 1970's reassembly bolted in place. In thinking about this the mounting plate connection for the pivot will be bolted in place. It would appear to the that the original mounting bracket was riveted into the side frame at a joint judging by the existing torched material. At this time we will probably torch out some of the rivets at the connection point then bolt the pivot mounting bracket in there. If necessary for historical accuracy the exposed heads of the bolts may be riveted over

As well Bill and I discussed some of the parameters for turntable construction and improvements. To keep with the historic nature of the site and keep modern safety considerations in mind, reconstruciton is done to an aesthetically pleasing but functionally safe standard. For example the new locking mechanism to lock the turntable to the tracks will be moved outside the rails to eliminate the need for someone to be in the gauge to lock the turntable. As well the new turntable arms will be made of steel and made to look like wood in all likelihood. Wooden arms are nice but they can break and require more maintenance.

Tuesday, January 17, 2017

Reflections on reading technique and project scheduling

My Dearest Reader,

I hope a degree of levity is appreciated in these postings as I greatly enjoy it.

The SQ3R reading technique is interesting. I've never had it explicitly stated that way but I have found for many years that I've gotten in the habit of doing it without realizing it. When I read, if it is something of substance that I care to take interest in, I will read it, write questions and comments in the margins, and when I find a puzzling passage I will often read it out loud and try to rephrase it in my own words. My high school was heavy in the humanities and I was regularly required to read well over a thousand pages of text every semester if not several thousand. I tend to read histories, biographies, and theologies in my spare time which does required a bit of adjustment in reading practice compared to more technical texts.

The reading on scheduling was interesting. The thing it reminded me the most of was limiting reactants in chemistry. A project schedule can be viewed as a series of chemical reactions dependent upon their predecessors for continuation. Taking this to a real life example, when I was taught how to restore historic wooden railroad equipment I was taught to fix the frame and running gear first, then go to the roof, then deal with the body of the car, and finally the interior trimmings. You could have the best body and roof every built on a car, but if the frame of the car is garbage all the work that was done will be ruined in a few years.

I find that I myself am susceptible to imposter syndrome. I try to maintain a growth mindset as much as possible towards intellectual pursuits.

I hope a degree of levity is appreciated in these postings as I greatly enjoy it.

The SQ3R reading technique is interesting. I've never had it explicitly stated that way but I have found for many years that I've gotten in the habit of doing it without realizing it. When I read, if it is something of substance that I care to take interest in, I will read it, write questions and comments in the margins, and when I find a puzzling passage I will often read it out loud and try to rephrase it in my own words. My high school was heavy in the humanities and I was regularly required to read well over a thousand pages of text every semester if not several thousand. I tend to read histories, biographies, and theologies in my spare time which does required a bit of adjustment in reading practice compared to more technical texts.

The reading on scheduling was interesting. The thing it reminded me the most of was limiting reactants in chemistry. A project schedule can be viewed as a series of chemical reactions dependent upon their predecessors for continuation. Taking this to a real life example, when I was taught how to restore historic wooden railroad equipment I was taught to fix the frame and running gear first, then go to the roof, then deal with the body of the car, and finally the interior trimmings. You could have the best body and roof every built on a car, but if the frame of the car is garbage all the work that was done will be ruined in a few years.

I find that I myself am susceptible to imposter syndrome. I try to maintain a growth mindset as much as possible towards intellectual pursuits.

First Post for Construction Engineering

Construction Engineering, preconceptions and learning outcomes

What do I think construction engineering is? I think construction engineering is the shepherding of a design from paper to reality. It requires two commonly divergent qualities, a proficient technical background and ability to communicate with many different groups.

A good construction engineer must be able to understand from a technical perspective what is being done and be able to see if any gross errors have been made. As well he or she must be able to properly assess and handle whatever unexpected technical problems that arise, i.e. a pipe where there wasn't supposed to be one or how do we get the generator into the basement after we poured the first floor.

As well a good construction engineer is a good manager and communicator. He or she must have a decent idea of what is going on at all times and how all these things interact. Like a conductor in a symphony directing the orchestra the construction engineer oversees the craftsmen in their trades. The engineers job is to make sure that all relevant parties are on the same page at all times and their actions compliment not conflict each other.

I want to go into construction engineering for my career, or at least initially. I want to learn from a classroom perspective how to be a better construction engineer and manager. As for first impressions, I find the flipped classroom refreshing and engaging. This is not a class I will be falling asleep in.

Welcome to the 14th Street Backshop

Hi Everybody!

So you may be wondering why does this exist and why am I sharing my often rambling thoughts and creations with the world. Long story short this blog serves two purposes. For my construction engineering class I need to have a blog and also I will be documenting my engineering work on the Como Turntable with it! So welcome to a world of required coursework intertwined with antiquated engineering acts (mild alliteration is a habit sorry)

Why is it called the 14th Street Backshop? In railroading a backshop is where major maintenance goes on. Typically it is a shop in back of the roundhouse or in back of something, ere go the name. We persons of a railroad persuasion are a creative bunch. The 14th Street comes from my address, I live on 14th street, again with that whole being creative thing.

Welcome, welcome all. If you are a construction engineering student engaged in coursework or a railfan looking at my work, welcome.

Leighton Moreland

So you may be wondering why does this exist and why am I sharing my often rambling thoughts and creations with the world. Long story short this blog serves two purposes. For my construction engineering class I need to have a blog and also I will be documenting my engineering work on the Como Turntable with it! So welcome to a world of required coursework intertwined with antiquated engineering acts (mild alliteration is a habit sorry)

Why is it called the 14th Street Backshop? In railroading a backshop is where major maintenance goes on. Typically it is a shop in back of the roundhouse or in back of something, ere go the name. We persons of a railroad persuasion are a creative bunch. The 14th Street comes from my address, I live on 14th street, again with that whole being creative thing.

Welcome, welcome all. If you are a construction engineering student engaged in coursework or a railfan looking at my work, welcome.

Leighton Moreland

Subscribe to:

Posts (Atom)